Ever wondered how DTF printing works? This guide is your key, not just to understanding the process, but also to learning the pro tips that will elevate your skills.

Whether you’re a small shop owner, a growing brand, or managing a large-scale business, understanding the process is crucial to selecting the right supplier. At American HTV, we don’t just print and ship; we give you the confidence that your designs are handled with care, from the moment you submit your file to the final peel.

What is DTF Printing?

DTF printing is the most versatile way to customize apparel. Unlike traditional methods like screen printing, DTF works on almost any fabric type or color. This means you aren’t limited to just cotton or light-colored shirts.

It is a transfer that you can apply to cotton, polyester, blends, canvas, hoodies, tote bags, essentially anything. This is why DTF is the top choice for everyone from hobbyists to large businesses.

Why should you choose Custom Printing?

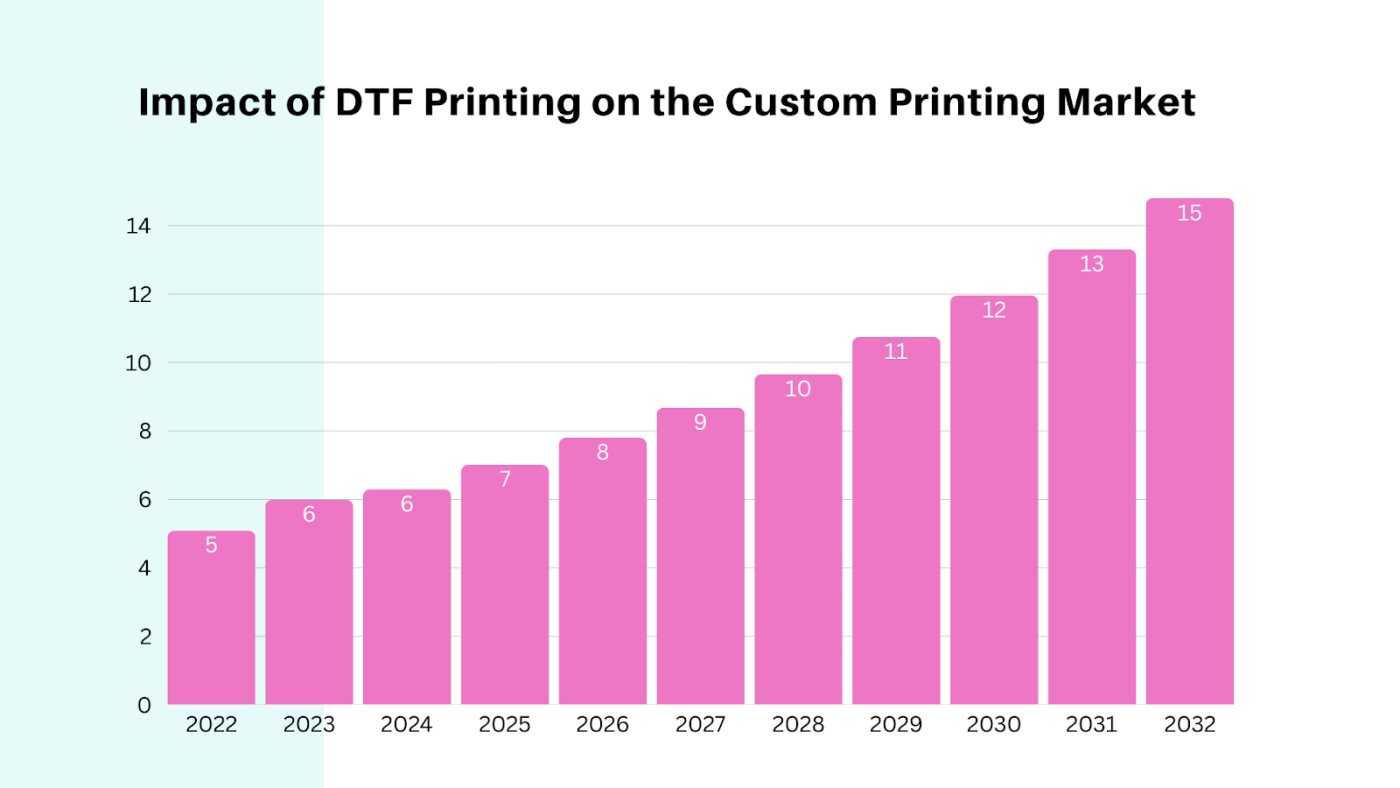

According to a recent market analysis, the custom t-shirt printing industry was worth USD 5.09 billion globally in 2022. The market is on a path of rapid expansion, with projections estimating its value will swell to roughly USD 14.81 billion by 2032. This forecast indicates a compound annual growth rate (CAGR) of 11.27% from 2023 through 2032, highlighting a lucrative period for businesses within this market

How DTF Printing Works? (Step by Step)

At American HTV, we believe in full transparency, which is why we want you to know exactly what happens behind the scenes after you place your order. Our DTF printing process is a carefully managed workflow designed for speed, precision, and quality.

From the moment your design file is uploaded, it goes through a series of steps, including artwork preparation, printing, powder application, and curing, all handled with professional care. This detailed workflow ensures that every transfer we produce is high-quality, durable, and ready to be pressed onto your final product, giving you complete confidence in the result.

1. Artwork Preparation

The first step is crucial. Your design file is thoroughly checked by our experts to ensure it has the correct resolution, dimensions, and accurate colors. Clean files result in clean prints, so we take the time to optimize every design and confirm it’s perfect before it ever reaches the printer.

2. Printing on PET Film

Once the artwork is ready, the design is printed onto a specialized PET (polyethylene terephthalate) film. We use high-quality DTF printers and premium inks, which are designed to capture every fine detail and produce colors that are both vivid and true to your original design.

3. Applying Adhesive Powder

Immediately after printing, while the ink is still wet, a fine, uniform layer of adhesive powder is carefully applied. This special powder is a key part of the process, as it’s what creates a strong, lasting bond between the transfer and your garment.

4. Curing the Design

Next, the film, now coated with adhesive powder, goes through a precise curing process. It’s heated at a specific temperature to melt and bond the adhesive powder to the ink. This step is what makes the final transfer incredibly durable, resistant to washing, and ensures the colors stay bright over time.

5. Heat Pressing

When your transfers arrive, the next step is simple. All you need is a heat press. You’ll place the film with the design on your garment and apply the correct time, temperature, and pressure. This is where the transfer is fully activated and bonded to the fabric.

6. Peel & Finish

After the heat press cycle is complete and the transfer has cooled slightly, you can peel away the PET film. You’re left with a professional-grade print that has a smooth, flexible feel and a permanent, high-quality finish.

What are the Advantages(pros) of DTF Printing?

DTF is known for its incredible versatility. Unlike other printing methods, it can be applied to almost any type of fabric or color, from cotton and polyester to blends and beyond. This makes it a great all-in-one solution for anyone printing on a variety of apparel. Here are the key advantages of using DTF for your projects:

- Works on Any Fabric: It works on almost any fabric type, from cotton to polyester and blends, regardless of the color.

- Vibrant Prints: It produces bright, full-color designs that are incredibly vivid, making it perfect for gradients and detailed photos.

- Exceptional Durability: The prints are long-lasting, resistant to cracking, and hold up well to repeated washing.

- Flexible for Any Order Size: DTF is efficient for creating a single custom transfer or for high-volume production runs.

- Simplified Process: There’s no need for weeding, cutting, or the pre-treatment of garments, which saves you a lot of time and effort.

- Convenient to Store: Unused transfers can be easily stockpiled and stored for future use, allowing you to print designs in advance.

What Are the Cons(Disadvantages)of DTF Printing?

While DTF is a fantastic option, it’s important to be aware of a few potential drawbacks. Understanding these helps you get the best possible results.

- Requires a Heat Press: For a successful application, you must use a heat press with the correct time, temperature, and pressure settings. Using an iron or a manual press may not provide a consistent result.

- Slightly Heavier Feel: Unlike sublimation, where the ink becomes part of the fabric, a DTF transfer sits on top of the material. This gives it a slightly thicker, heavier feel compared to the smooth, undetectable feel of a sublimation print.

- Storage Needs: The transfers themselves require proper storage. To keep them in perfect condition, they should be stored away from moisture, direct sunlight, and extreme heat, as these can damage the adhesive and film.

At American HTV, we’ve already solved these challenges for you. Our transfers arrive pre-optimized and cured, so you can skip the complex steps. Just heat, press, peel, and you’re done.

Why Our Process Matters

Every step of our process, from selecting the right film to the final curing, directly impacts the quality of your finished transfer. Taking cheap shortcuts can result in faded colors, poor stretch, or prints that peel after just a few washes.

At American HTV, we invest in premium films, top-quality inks, and a precise curing method to ensure your transfers not only look vibrant but also last longer. When you order from us, you’re not just buying a transfer; you’re getting a process that has been perfected to deliver professional-grade quality, every single time.

How does a DTF Printer Work?

Stepping into the world of DTF printing, whether as a new venture or an expansion of an existing one, means getting acquainted with a specific set of tools. Unlike other printing methods, DTF relies on a cohesive system of specialized equipment and consumables working in tandem. Investing in this technology doesn’t have to be overwhelming, and understanding the role of each component is the first step toward producing impeccable results consistently.

1. The DTF Printing Machine

At the very core of this entire operation sits the DTF printer itself. These are not your typical office inkjet devices; they are specifically engineered or modified for the unique requirements of Direct-to-Film transfers. The standout feature of these printers is their ability to accommodate a full set of colors, Cyan, Magenta, Yellow, and Black, alongside a crucial, dedicated channel for white ink.

Furthermore, a key advancement in this technology is the redesign of the paper feed system. These printers often lack the traditional rollers that could previously create lines or marks on the page. This innovation ensures that the vital white underbase, which is the foundation of every vibrant print, remains perfectly smooth and unblemished, guaranteeing a flawless final transfer.

2. The DTF Transfer Films

The canvas for your DTF creation is a specialized material known as PET film. These films are the medium onto which your design is printed and subsequently transferred. With a typical thickness of around 0.75mm, they are robust enough to withstand the printing and heat-pressing processes without buckling, ensuring superior transfer characteristics.

These films are available in various formats to suit different operational scales. Individual cut sheets are ideal for smaller projects or home-based businesses, while large rolls are designed for high-volume commercial production. The films are also distinguished by how they are handled after the heat press:

- Cold-Peel Films are designed to be peeled away only after the transfer has fully cooled.

- Hot-Peel Films allow for immediate peeling, which can speed up production.

3. The Crucial Role of Software

Software is far more than just a driver in DTF printing; it is a mission-critical component that dictates the final quality of your print. To properly manage the layers of colored and white ink, you must use a specialized RIP (Raster Image Processor) program. This software serves as the brain of the operation, translating your digital design into precise print instructions.

A high-quality RIP program is indispensable because it manages all the technical parameters that influence print performance. It is responsible for:

- Color Accuracy: Using custom color profiles to ensure your final print matches your on-screen design.

- Ink Control: Precisely controlling the size of ink drops and the flow of ink to prevent oversaturation or banding.

- Layering: Ensuring the white ink underbase is laid down perfectly to provide a solid, opaque foundation for the colors.

4. The Hot-Melt Adhesive Powder

The hot-melt adhesive powder is the “molecular glue” that forms a permanent bond between the ink and the fabric. This fine, white, granular substance is meticulously applied to the wet ink on the transfer film. When heated, this powder transforms, melting into a powerful adhesive layer that permanently fuses the pigments to your chosen garment. The quality and grade of this powder are crucial, as they directly impact the final transfer’s durability and wash resistance.

5. The Unique DTF Inks

The inks used in DTF are unique pigment formulations, distinct from standard printer inks. This ink set includes the traditional Cyan, Magenta, Yellow, and Black (CMYK) pigments, but it is the dedicated White ink that truly sets this system apart. The white ink is the first to be printed on the film, creating a solid, opaque layer. The colored pigments are then printed on top of this white base, allowing them to appear bright and true-to-color on any fabric, regardless of its color.

6. Automated Curing and Powdering Systems

For businesses focused on high-volume production, specialized machinery streamlines the curing and powdering process.

- Automatic Powder Shaker: This component ensures a perfectly even and consistent application of the hot-melt powder. It automatically coats the printed film and shakes off any excess, eliminating waste and ensuring a uniform adhesive layer for every print.

- Curing Oven: This industrial oven melts the adhesive powder with a controlled, consistent heat. It is a more efficient alternative to a heat press, ensuring a uniform cure across the entire print and preparing it for transfer.

7. The Indispensable Heat Press

No DTF process is complete without a professional heat press machine. This piece of equipment is essential for two key functions:

- Curing: In smaller setups, the heat press can be used to cure the adhesive powder by hovering over the film without direct contact.

- Final Transfer: The primary role of the heat press is to apply the final heat and pressure required to transfer the design from the film to the garment. The heat reactivates the cured adhesive, and the pressure ensures a strong, permanent bond. Correctly managing the time, temperature, and pressure is crucial for a durable, long-lasting print.

How is DTF Printing Different From Other Printing?

How is DTF Different From DTG Printing?

While both DTF and DTG are popular digital printing methods for apparel, they have some key differences that make them ideal for different projects.

DTG (Direct-to-Garment): It is also known as a giant inkjet printer for shirts. The machine prints ink directly onto the fabric, where it soaks into the fibers. This method is great for 100% cotton and creates a soft, breathable print. However, it’s not ideal for synthetic fabrics or for producing very bright colors on dark garments.

DTF (Direct-to-Film): This is a two-step transfer process. Your design is printed onto a special film, coated with an adhesive powder, and then cured. This creates a ready-to-use transfer. DTF transfers are incredibly versatile and can be applied to almost any material, including cotton, polyester, and blends. The transfers feel slightly raised but are flexible and produce vibrant, bold colors on any garment, dark or light.

| Difference | DTF Printing | DTG Printing |

|---|---|---|

| Process | Prints to a film, then heat-pressed onto a garment. | Prints directly onto the garment. |

| Ideal Fabrics | Any fabric type: cotton, polyester, blends, nylon, etc. | Best for 100% cotton and natural fibers. |

| Look & Feel | Slightly raised, smooth, and flexible feel. | Soft feel, part of the fabric itself. |

| Color | Bright, vibrant, and opaque on any garment color. | It can be less vibrant on dark fabrics. |

| Versatility | Highly versatile. One transfer works on many materials. | Limited to a narrower range of fabric types. |

How Does DTF Differ From White Tone Printing?

DTF Printing:

DTF printing utilizes a modified inkjet printer with specialized, water-based inks to print designs directly onto a clear polyethylene terephthalate (PET) film. Once the design is printed, a powdered adhesive is applied to the wet ink, and the film is then heated to cure it. The final image is then transferred onto the desired material, such as cotton, polyester, and their blends, using a heat press.

- Benefits:

- Produces incredibly soft, flexible, and durable prints with excellent stretch resistance.

- Perfect for clothing, as the prints can endure numerous wash cycles without significant cracking or fading.

- Delivers superior color saturation and highly detailed image reproduction.

- Drawbacks:

- Requires more frequent upkeep than white toner printers because the liquid inks can easily clog if the machine is not used regularly.

- The process includes a separate step for applying and curing the adhesive powder, which can be messy and needs proper ventilation to manage fumes.

White Toner Printing:

White toner printing is a laser-based process that employs a specialized printer containing a white toner cartridge in addition to the standard CMYK (Cyan, Magenta, Yellow, Black) toners. The white toner is often applied as a base layer, enabling vibrant colors to stand out on dark or colored substrates. The design is printed onto a specific transfer paper and then applied with a heat press.

- Benefits:

- Requires minimal maintenance and can be left unused for extended periods without the risk of clogged components.

- Extremely adaptable, allowing for printing on a wide array of materials beyond textiles, including wood, metal, glass, and ceramics.

- The process is very quick, making it efficient for producing small batches and unique custom items.

- Drawbacks:

- Prints on fabric may have a thicker or more “plastic” feel and could be more susceptible to cracking or peeling after several washes compared to DTF prints.

- The initial investment for the equipment can be higher than that of a basic DTF setup.

What Is The Difference Between DTF & Sublimation Printing?

Many people get DTF and sublimation printing mixed up, but they are two very different methods. While both techniques rely on heat, their processes and results are distinct. The key differences between them are:

DTF Printing

DTF printing is a modern method that uses a two-step process to create durable transfers. The design is first printed onto a specialized film using a DTF printer. While the ink is still wet, an adhesive powder is applied and then cured with heat. This process creates a transfer that can be heat-pressed onto a wide variety of materials, including cotton, polyester, and their blends. The result is a vibrant, durable, and slightly flexible design that sits on top of the fabric. Some of its features are given below:

- Works on cotton, polyester, blends, darks, and lights.

- Durable, stretchy, and vibrant colors.

- No coating or pretreatment needed.

- Transfers can be stored and used later.

Sublimation Printing

Sublimation is a process that relies on a chemical reaction to fuse ink directly into the fibers of a material. The design is printed onto special transfer paper using sublimation inks. When this paper is pressed onto a polyester-based garment with heat, the inks turn into a gas and are permanently absorbed by the fabric. The final print is incredibly vibrant and feels completely smooth to the touch because the ink has become a part of the material itself. Some of its features are given below:

- Limited to polyester or polyester-coated items.

- Works best on white or very light fabrics.

- Produces a softer “no feel” finish.

- Cheaper entry setup, but less versatile.

What Is The Difference Between DTF and Screen Printing:

DTF (Direct-to-Film) printing and screen printing are two distinct methods for apparel decoration, each with its own process, cost, and ideal use case. Screen printing is a traditional, stencil-based technique highly suited for large-scale production of simple designs. In contrast, DTF is a modern, digital process better suited for smaller orders and intricate, multi-colored designs.

DTF Printing

DTF printing is a digital method where a design is printed onto a specialized film and then transferred to a garment using a heat press. This process requires a specific printer, ink, and adhesive powder.

- Process: A design is printed onto a PET film using a specialized DTF printer. A powdered adhesive is applied to the wet ink on the film. The film is then heat-cured, and the design is applied to the fabric using a heat press.

- Ideal Use: DTF is optimal for small orders, complex designs, and full-color photographic images. The absence of a need to create separate screens for each color makes the setup efficient and cost-effective for low-volume or single-item production.

- Fabric Compatibility: This method is highly versatile and works on a wide range of materials, including cotton, polyester, blends, and nylon, on both light and dark fabrics.

- Tactile Quality and Durability: The print rests on the fabric’s surface, resulting in a slightly raised or smooth, plastic-like feel. The print is durable and resistant to cracking and peeling.

Screen Printing

Screen printing is a classic, manual process that uses a mesh screen as a stencil to apply ink directly onto a fabric. A unique screen is required for each color in the design.

- Process: A stencil is created on a mesh screen for each color in the design. Ink is then pushed through the stencil’s open areas onto the fabric using a squeegee. The garment is subsequently cured with heat to set the ink.

- Ideal Use: Screen printing is most efficient for large-volume orders of simple designs with a limited number of colors. The high initial setup cost is justified by a significantly lower cost per item in bulk production, making it highly cost-effective for large-scale runs.

- Fabric Compatibility: It is most frequently used on cotton and cotton-blend fabrics.

- Tactile Quality and Durability: The ink is absorbed into the fabric fibers, creating a softer, more integrated feel. Screen prints are renowned for their exceptional durability and wash-resistance, often outlasting the garment itself.

What You Can Print On with DTF

DTF printing offers a remarkable level of flexibility. Unlike other methods that have strict material requirements, this technique can be used on a wide array of fabrics and items, making it an excellent choice for a diverse product line.

- Cotton shirts: DTF creates sharp, vivid designs on classic cotton tees.

- Polyester activewear: The transfers bond perfectly with performance fabrics, making them a great choice for sportswear.

- Hoodies & sweatshirts: Easily apply designs to thicker garments for a soft, durable result.

- Tote bags: DTF works wonderfully on canvas bags, perfect for branding or custom artwork.

- Canvas & denim: Add unique, detailed prints to durable materials like canvas and jeans.

- Jackets: Customize outerwear with professional, long-lasting results.

- Blends & specialty fabrics: DTF is compatible with a wide variety of blends and other unique textiles.

What You Need for DTF Printing

These tools are what make it all happen. They work together to turn your design into a final product. Here is a simple list of the things you will need to get a great result.

The DTF Printer: This is a special kind of printer. It prints all the normal colors (CMYK) plus a special white color. This lets your designs look bright on any shirt, even on dark ones.

The Heat Press: A heat press uses heat and pressure to put your design onto the shirt. It makes sure the design sticks and stays on for a long time. It is the final step in the process.

The Automated Duo: Powder Shaker and Curing Oven: If you plan to make many shirts, these are very helpful. The shaker puts the special powder on your prints. The oven melts the powder with even heat. This makes the transfers ready to use very fast.

DTF Inks: These inks are like the paint for your project. They are made to be very bright and stretchy. The white ink is very important because it acts as a base layer. This makes your colors show up on any color shirt.

DTF Transfer Films: This is the sheet you print your design on. It is made to hold the ink and then release it perfectly onto the fabric when you press it. This material is what makes the whole transfer process work.

Hot-Melt Adhesive Powder: This is a fine powder that is put on top of the wet ink. When you heat it, it melts and becomes a kind of glue. It makes your print stick to the shirt so it won’t crack or peel.

How to Get Your Colors Right?

Making sure your colors look the way you want them to is a big deal. With DTF, a little bit of knowledge helps a lot. It is how you get your colors to be perfect every time.

The Color Difference: RGB and CMYK: The colors you see on your computer screen are RGB colors. Your printer uses CMYK inks. Without a special tool, this can cause your colors to look dull.

Your Special Tool: RIP Software: This is a special program for your computer. It helps close the gap between your screen and your printer. It uses special settings to make sure the colors you see on your computer print correctly. It is the program that tells your printer exactly what to do.

Matching Colors for Brands: If you are making shirts for a business, they may need an exact color. This is called Pantone matching. While DTF cannot match every color perfectly, your special software can get very close. This is a great way to make sure your work looks professional.

The Top Rule for DTF: Perfect Files

A good DTF print always starts with a good file. Getting this right from the beginning will save you from making mistakes. Follow these easy rules every time you make a new design.

Choose a PNG: The best type of file for DTF is a PNG. The main reason is that it can have a clear, empty background. This is very important for printing.

Make it Transparent: Your design file must have a clear background. If there is a white box behind your design, the printer will print that box. This is a common mistake you want to avoid.

Do Not Lower the Quality: Your design should always be at 300 DPI. This stands for Dots Per Inch. Making sure your file has this much detail will make your print look clean and sharp. You will not see any blurry parts.

Why is DTF a Smart Choice?

DTF is not just a great way to print; it is also a good way to make money. Here is why many businesses choose DTF to make a profit.

Low Cost Per Print: Unlike other methods, DTF does not require a lot of setup for each design. You just print and press. This makes the cost for each shirt very low. It is a good way to make a lot of money, even on small orders.

A Quick Profit: The cost to start a DTF business is not very high. This means you can start making money very quickly. You can take on small orders that other printing companies would not do. This helps you build your business and make a profit fast.

How to Make Your Prints Last?

DTF prints are made to be strong, but a little care can help them last a long time. These simple tips will help your designs look great for years.

Wash Inside Out: Always turn the shirt inside out before washing it. This protects the design from rubbing against other clothes.

Keep it Cool: Wash the shirt in cold water on a gentle setting. High heat can hurt the design and cause it to crack. You should avoid hot water and strong soaps.

Let it Air Dry: The heat from a dryer can also hurt the print. For the best results, let the shirt air dry. If you must use a dryer, use the lowest heat setting.

How Is DTF Printing A Good Choice for the Planet?

DTF can be a more environmentally friendly choice. The inks used are water-based and safe. They do not have dangerous metals or chemicals that are in some older types of inks. This makes DTF a safer choice for both your business and the planet.

Why Do Businesses Choose DTF?

Businesses of all sizes are choosing DTF because it offers significant advantages throughout their entire workflow.

- Speed: DTF provides a fast turnaround and is easily scalable, allowing you to produce anything from a single piece to thousands.

- Flexibility: This single printing method can be used on a wide range of garment types, from cotton tees to polyester hoodies, simplifying your production process.

- Profitability: For smaller and medium-sized orders, the cost of DTF is much lower than the expensive setup fees associated with traditional screen printing.

- Scalability: You can print and store transfers in advance, then press them onto garments as orders come in. This allows you to manage your inventory efficiently and scale your business without a huge upfront investment.

For these reasons, everyone from small businesses and growing clothing brands to large-scale resellers trusts American HTV to help them keep their production running smoothly and efficiently.

Frequently Asked Questions (FAQs)

What’s the first step in the DTF printing process?

It all starts with your digital artwork. You need a print-ready file with the correct settings for color, resolution, and transparency.

How does the design become a transfer?

A specialized DTF printer prints your design onto a special film. The colors are printed first, followed by a white layer that makes the design opaque and vibrant.

What makes the transfer stick?

While the ink is still wet, a fine adhesive powder is applied. This powder is then cured with heat, forming a solid layer that will bond to your garment later.

How do I apply for the transfer?

You simply use a heat press to apply the transfer to your garment. The heat reactivates the adhesive, permanently bonding the design to the fabric.